Technology • 11.03.2024

5 reasons to use the PolarVisor web application to monitor refrigeration systems

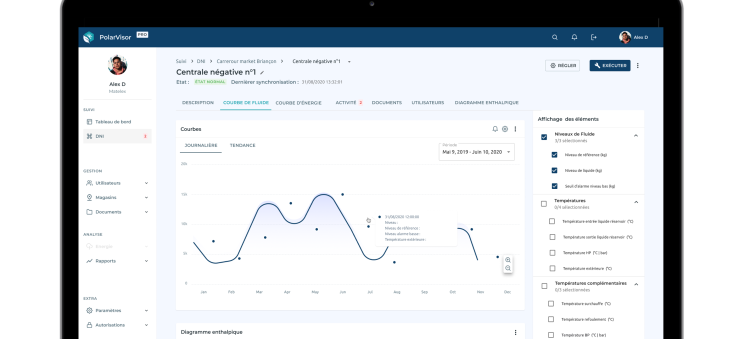

Matelex launches its new web platform for monitoring refrigeration installations, PolarVisor. Its promise: improved ergonomics and new functions to make it easier to manage a fleet of refrigeration plants. Co-developed with refrigeration professionals, Matelex technology allows you to monitor the operation of your installations remotely from a simple web browser. As soon as a refrigerant leak, energy drift or risk of failure appears, operators are alerted.

Discover the 5 reasons why PolarVisor is such an important ally in the management of refrigeration installations.

1 – Easily monitor refrigeration systems with the PolarVisor dashboard

With the PolarVisor dashboard, you can check at a glance that your refrigeration system is operating correctly. In addition, a map and visual indicators make it easier to locate and qualify alerts.

In practice, alarms and alerts are displayed as a priority in the event of :

- refrigerant leak (low level alarm and statistical alarm),

- energy drift,

- risk of compressor failure,

- sensor faulty, incorrectly calibrated or incorrectly configured.

What’s more, the dashboard is enhanced by advice. PolarVisor offers a reminder of the regulatory checks to be carried out and suggestions for improving the settings of the installations.

2 – View refrigerant levels precisely with the PolarVisor web application

Detecting faults, particularly refrigerant leaks, is the first step. But this is still not enough. It is important to investigate in order to better understand the event and to prepare the response. That’s why the PolarVisor web application displays detailed contour lines and trend lines for the selected period.

How does it work?

Numerous filters provide detailed information to help you analyse events and display additional details (pressures, temperatures, etc.).

When it comes to events, one click is all it takes to display alarms and refills. This will simplify the monitoring of installations and provide a shared, real-time view between all the players involved.

The global dashboards provide the following information:

- A map of the installations with the control units in alarm;

- trend curves and daily curves ;

- display of additional data via filters (pressures, temperatures, etc.);

- declaration of fluid refills ;

- display of recharges and alarms directly on the curves.

3 – Efficiently control the energy consumption of refrigeration systems

Refrigeration operators can use their web browser to connect to PolarVisor and find all the information on motor consumption: compressors, condenser fans and pumps for indirect circuits. In this way, refrigeration professionals can recover the actual coefficients of performance (COPs) of their installations. They are also alerted in the event of energy drift or risk of premature compressor wear.

What are the direct benefits of this system?

Users have access to precise data on a daily basis, enabling them to adjust the settings of their refrigeration systems and improve their performance.

In practical terms, PolarVisor offers :

- advice on how to improve the settings of your installation ;

- fully autonomous configuration changes: LP and HP set points, receiver and condenser volume, choice of compressor type, LP and HP pressure range settings, temperature sensor calibration, etc. ;

- immediate and remote visualisation of the impact of adjustments.

4 – Get real-time information for optimised refrigeration plant performance

Against a backdrop of labour shortages and climate change emergencies, PolarVisor is providing new information to simplify the management of refrigeration plants.

All the functions of the new web application allow users to :

- continuous, real-time information, the equivalent of having a technician on site 24/7;

- prioritise interventions according to the condition of the fleet and the criticality of alarms;

- avoid unnecessary journeys: if a leak occurs, an alert will be sent out,

- adjust plant settings to improve operation;

- A shared view between operators and plant owners;

- Reduce the overall environmental impact of facilities by reducing direct (leaks) and indirect (energy) greenhouse gas emissions.

5 – Benefit from a tailor-made digital service to reduce CO2 emissions from refrigeration installations

The Matelex solution enables refrigeration professionals to switch to high-performance digital technology. This optimises plant operation and simplifies management. It provides access to a comprehensive range of services tailored to the real needs of refrigeration professionals.

Sentinelle, the previous platform, has already prevented the emission of thousands of tonnes of CO2 equivalent from more than 2,000 refrigeration plants. PolarVisor has been designed to reduce direct greenhouse gas emissions and further promote energy savings. And all this thanks to control that is as close as possible to actual operation. Above all, it’s a question of measuring to better manage a fleet of facilities.