Regulations, Technology • 10.10.2024

Refrigerant leaks: how to detect them early

The European refrigeration sector is experiencing sustained growth, with the commissioning of 600 million m2 of refrigerated warehouses and 5.6 billion air conditioners by 2050. At the same time, the European Commission has announced its intention to reduce greenhouse gas emissions by 55% by 2030. To meet this major environmental challenge, doing everything possible to detect and seal refrigerant leaks in good time is becoming a regulatory obligation, but above all a social one.

What leak detection methods are available and what do French and European regulations say on the subject?

Refrigerant leaks: Regulatory update

Since 1987, the Montreal Protocol has regulated ozone-depleting substances such as chlorofluorocarbons (CFCs).

In 1997, the Kyoto Protocol addressed greenhouse gases such as hydrofluorocarbons (HFCs). In 2006, Europe introduced the first version of the F-Gas Regulation to regulate the sale and use of refrigerants.

Its second version, EU Regulation No. 517/2014, came into force on 1 January 2015. It sets out best practices for limiting emissions from refrigerants. It also sets quotas for the quantity of fluids placed on the market.

This regulation governs leak detection by requiring the installation of a detector to alert the operator in the event of refrigerant leaks, as well as regular leak checks, based on the tonnes of CO2 equivalent (T CO2 eq.) contained in the installations.

In 2016, a French decree went further than the European regulation and defined the authorised detection methods: direct and indirect detection.

In 2019, a new version of this decree defines the indirect measurement method as mandatory for installations containing quantities of refrigerants greater than 500 T CO2 eq. , soit 128 kg de R-404A.

In March 2024, the new European regulation ‘F-Gas III’ comes into effect. Here are the major impacts:

- HFOs must now undergo leak tests

- Installations containing quantities of unsaturated fluids (HFOs) greater than or equal to 100 kg or HFCs and HFC/HFOs greater than 500 tonnes of CO2 equivalent must be fitted with a permanent leak detection device such as the PolarBox or DNI. In the event of a leak, an alert must be sent out.

Frequency of leakage checks according to refrigerant categories and the new F-Gas III regulation and according to the French decree of July 2019 :

Important point: HFC HFO blends are considered to be HFCs.

The direct method: useful for finding local refrigerant leaks

Direct methods are not authorised in France for installations containing quantities of refrigerant in excess of 500 T CO2 eq.

They are nonetheless very useful in the search for local refrigerant leaks, although they do have certain limitations:

- They are used on an ad hoc basis, according to the periods defined by the regulations, and therefore do not provide constant surveillance. If a leak occurs the day after a visit, it will not be detected until the next visit (3 months, 6 months, etc.). The installation will then operate in a degraded manner, and may even stop production. Remember: a facility that is underloaded also consumes more energy.

- If they make it possible to locate a leak, there’s nothing to indicate that there isn’t another one. A complete search of all parts of the installation would be required to ensure that no leaks remain.

Direct and indirect methods complement each other!

Please note that any alarm triggered by a leak detection system using indirect measurement methods requires a leak to be located using a direct method.

The indirect measurement method: to identify refrigerant leaks as early as possible

To facilitate early detection of leaks

The method for detecting refrigerant leaks by indirect measurement is based on continuous analysis of at least one of the following parameters:

- The pressure ;

- Temperatures ;

- Compressor current ;

- Liquid levels ;

- The volume of the refilled quantity.

In the event of a drift in any of these parameters, the system must be able to trigger an alarm according to the following thresholds: 50g/h or 10% of the volume of the installation.

This permanent monitoring, coupled with an alarm system, makes the indirect measurement method a monitoring tool that is particularly well-suited to the early detection of refrigerant leaks.

And for effective remote identification of refrigerant leaks

The indirect measurement method, which analyses several parameters on a continuous basis, ensures constant monitoring of the installations.

That’s the whole point of this method of monitoring refrigerant leaks: to move from periodic leak checks to continuous monitoring.

It means that you can be alerted as soon as a leak occurs, so that you can take action as quickly as possible, and avoid a plant shutdown leading to a potential break in the cold chain, and high financial losses.

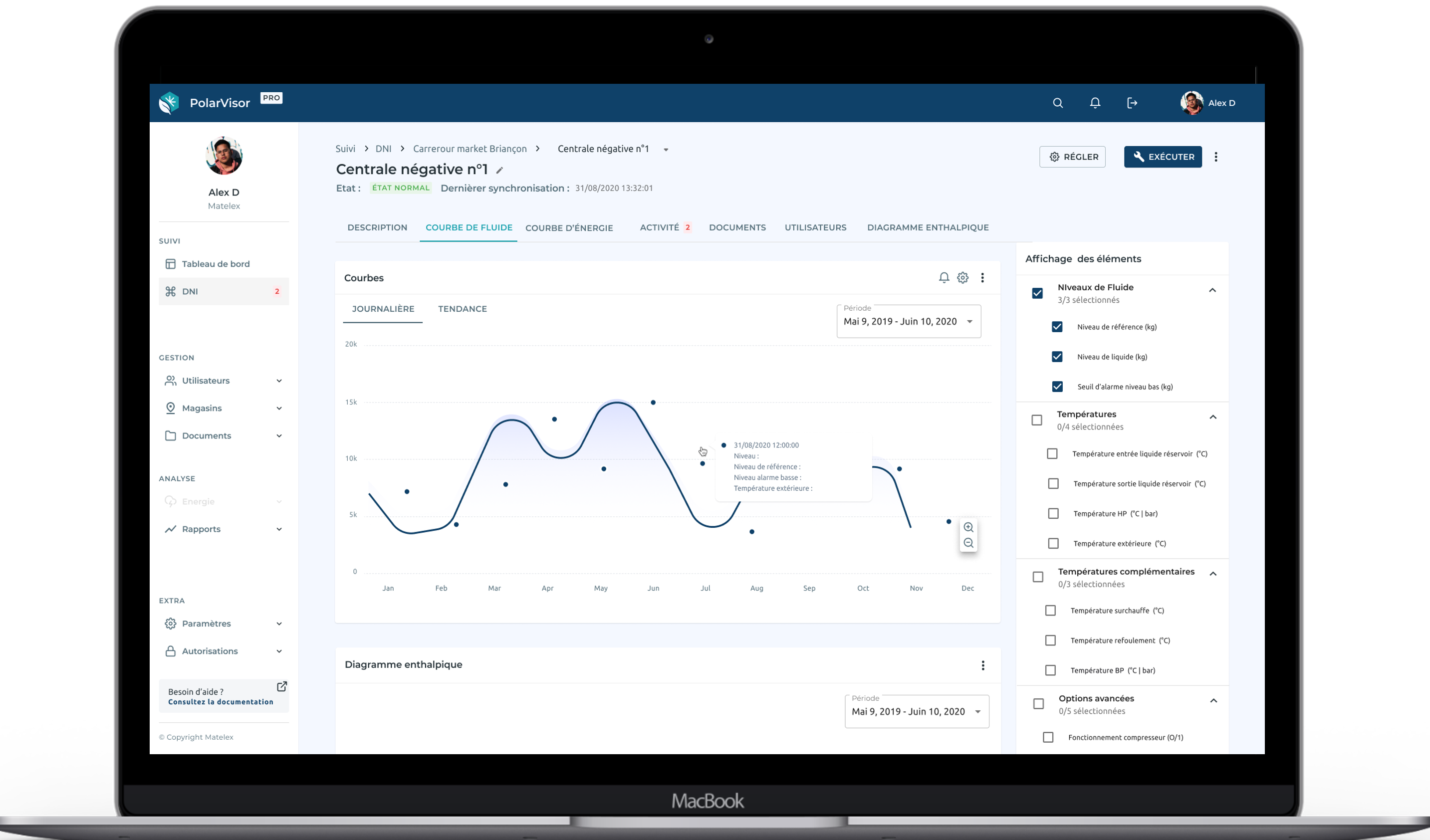

Connected to the internet, this type of method is particularly effective for remote monitoring of plant operation using Matelex’s PolarVisor web monitoring platform. As soon as a leak occurs, an alert is sent with an estimate of the leak rate and a deadline for taking action.

In brief: the different leak detection methods.

| Direct methods | Indirect methods |

|---|---|

| Portable detectors | Low level detector |

| surround controllers | Expert systems: P, T measurements, compressor current level, volume of recharged qty |

| Foaming solutions or soapy water | |

| Introduction of UV liquid or dye | |

| Vacuum wrapping | |

| Pressurisation |

Efficient fluid leak detection: do you know about expert systems (IoT)?

Low-level detection is one of the indirect methods available for measuring refrigerant leaks. How does it work? As soon as the fluid level falls below a set threshold, an alarm is triggered. This method is proving inadequate. It provides a late warning when the installation is almost empty and therefore about to shut down. It can also encourage systems to be undercharged, which has a major impact on their performance and leads to higher energy consumption.

Expert systems, on the other hand, operate on a simple principle: the demand for cooling varies constantly. For example, the demand for refrigeration in food superstores varies according to how busy the shop is: high on Saturdays when the windows are constantly opened and closed, low on Sundays when the shop is closed.

This involves differentiating between “normal” operation of an installation with fluctuating cooling demand that causes the refrigerant level to vary, and abnormal operation with a drop in level linked to a leak.

The emergence of the Internet of Things (IoT) and the introduction of algorithms are simplifying the identification of abnormal plant operation. After a learning period, a leak detection algorithm determines a reference level. Based on the refrigerant level in the liquid receiver (HP), this algorithm is then able to identify any deviation from normal operation.

Detect refrigerant leaks with the Matelex expert system

A test carried out on large-scale food retail refrigeration installations by the French Environment and Energy Management Agency (Ademe) highlighted the savings in refrigerant consumption that can be achieved by early detection of the algorithm.

The two detection methods used by Matelex were compared on a panel of 5 well-adjusted positive and negative installations:

- Traditional method: leak detection by direct method in accordance with regulatory inspection periods based on CO2 equivalent tonnage.

- Indirect method with expert system: detection by level measurement (fluid level weighing system and detection using the reference level determined by the algorithm).

Over a period of 6 months and in 5 shops with well-adjusted installations, the system saved the equivalent of 1,538 tonnes of CO2 by identifying leaks quickly (from 5 to 119 days earlier), representing refrigerant savings of 79% compared with a traditional method.

Matelex has also developed an energy module that calculates the consumption of compressors, condenser fans and pumps (indirect circuits). The combined installation of a DNI (Intelligent Level Detector) and this Energy module provides real-time monitoring of energy consumption and compressor operation, as well as early detection of refrigerant leaks. This dual approach makes it possible to identify direct and indirect greenhouse gas emissions and reduce them more effectively.