Technology • 10.10.2024

What are the benefits of IoT in the cold chain?

The Internet of Things (IoT or IoD) is playing an increasingly important role within companies. And refrigeration professionals are well aware of this. But how can we explain the growing success of the IoT, and why is its use now essential throughout the cold chain? We explain.

What is the Internet of Things?

First and foremost, we need to define what IoT is. As its name suggests, the Internet of Things (or IoD) refers to the interconnection between objects and the Internet. To do this, the equipment concerned is equipped with a computer system linked to a wireless network.

Connected objects can take many forms, from complex medical devices to simple coffee machines. This technology – when used in a professional context – enables, among other things :

- retrieve data in real time;

- analyse this data for strategic purposes;

- ensure better management;

- maintain remote control;

- be alerted in the event of a fault.

By way of background, a study by Ademe and Arcep, published in January 2022, claims that there were around 244 million connected objects in France at that time.

Why has integrating the IoT into the cold chain become essential?

Every year in France, 13,000 people go to hospital with food poisoning. Among the plausible explanations are a break in the cold chain or poor food preservation. It has to be said that between the harvesting and production of foodstuffs, storage, delivery and placing on the shelves, there can be major temperature differences. To give you an idea, the lack of effective refrigeration systems leads to the loss of around 526 million tonnes of food every year.

To ensure optimal monitoring of these products, the IoT appears infinitely more reliable than simple manual readings. With the right equipment, it is possible to :

- ensure continuous, high-performance refrigeration production;

- detect possible refrigerant leaks and related breakdowns and losses of goods;

- ensure that each product is traceable and kept cold;

- Reduce the environmental impact of refrigeration by reducing direct and indirect greenhouse gas emissions;

- optimise the operation of refrigeration facilities by monitoring their energy consumption (as a reminder, this accounts for around 50% of a supermarket’s final consumption).

In addition to these health concerns, integrating the IoT into the cold chain offers a number of advantages for a company. Whether from a logistical, economic or, in some cases, even ecological point of view, the benefits of the Internet of Things – and by extension Industry 4.0 – are winning over more and more decision-makers every year.

| Good to know: according to Irstea, around 60% of food passes through a refrigerated environment between production and arrival on our plates. |

What are the benefits of IoT for refrigeration professionals?

For professionals who have to manage low-temperature goods on a daily basis, the Internet of Things is now an indispensable tool. It is the obvious solution to many of the problems they encounter (lack of reliability, lack of data, etc.). Thanks to the IoT, we can obtain essential information on the operation of our facilities. The result is more efficient management through optimised use of the equipment installed.

So, when we talk about the advantages of installing a computer system on refrigeration equipment, the first thing to mention is the consistency, but also and above all the accuracy of the readings. There’s no longer any question of manually checking that fridges and freezers are working properly. Data collected in real time is sent automatically to the web application. This data can be used, for example, to monitor the tightness of systems, the efficiency of refrigeration production and, more generally, the associated energy consumption levels.

In fact, it is from this collected data that the beneficiaries of an IoT system can derive the greatest benefit: the early detection of equipment failures and refrigerant leaks. As a result, companies can make significant savings, both in terms of energy and money.

It is also worth noting that setting up an IoT system is recognised as being simple and inexpensive overall. Taking the Matelex solution as an example, no changes are required to the refrigeration plant. All you need to do is make sure that your installations are equipped with an HP liquid tank, and that’s it!

Last but not least, remote data collection means better preparation for interventions, and above all an end to unnecessary travel. It is no longer necessary to visit each site independently. You can manage your fleet of refrigeration plants more effectively, thanks to an overview of the plant, and only intervene when necessary.

| Good to know: the solution offered by Matelex can reduce a company’s refrigerant consumption by up to 80%! |

IoT: a fast-growing market that is attracting more and more businesses

Although France has lagged behind its European neighbours, more and more companies are turning to Industry 4.0 and gradually integrating IoT into their processes. According to the Révélations IoT 360 study, 24.7% of French companies surveyed were in the process of deploying a solution in 2023, compared with just 10.5% in 2022.

In a similar vein, we might mention a study carried out in 2022 by IDC for Kyndryl. Here we find that 48% of the companies questioned claim to be maintaining a stable budget in this area, while 43% say they would like to increase their budget for IoT.

In short, the Internet of Things is now a priority for many companies seeking to expand their business. Among the reasons cited, a survey of business leaders conducted by the PwC group lists the following in order of priority:

- modernising the brand through new skills ;

- continue to do what we know how to do more quickly and efficiently;

- change the company’s business model and redefine its strategic approach;

- integrate new markets.

| Good to know: predictive maintenance and asset tracking are the two areas most represented in the IoT market in France. |

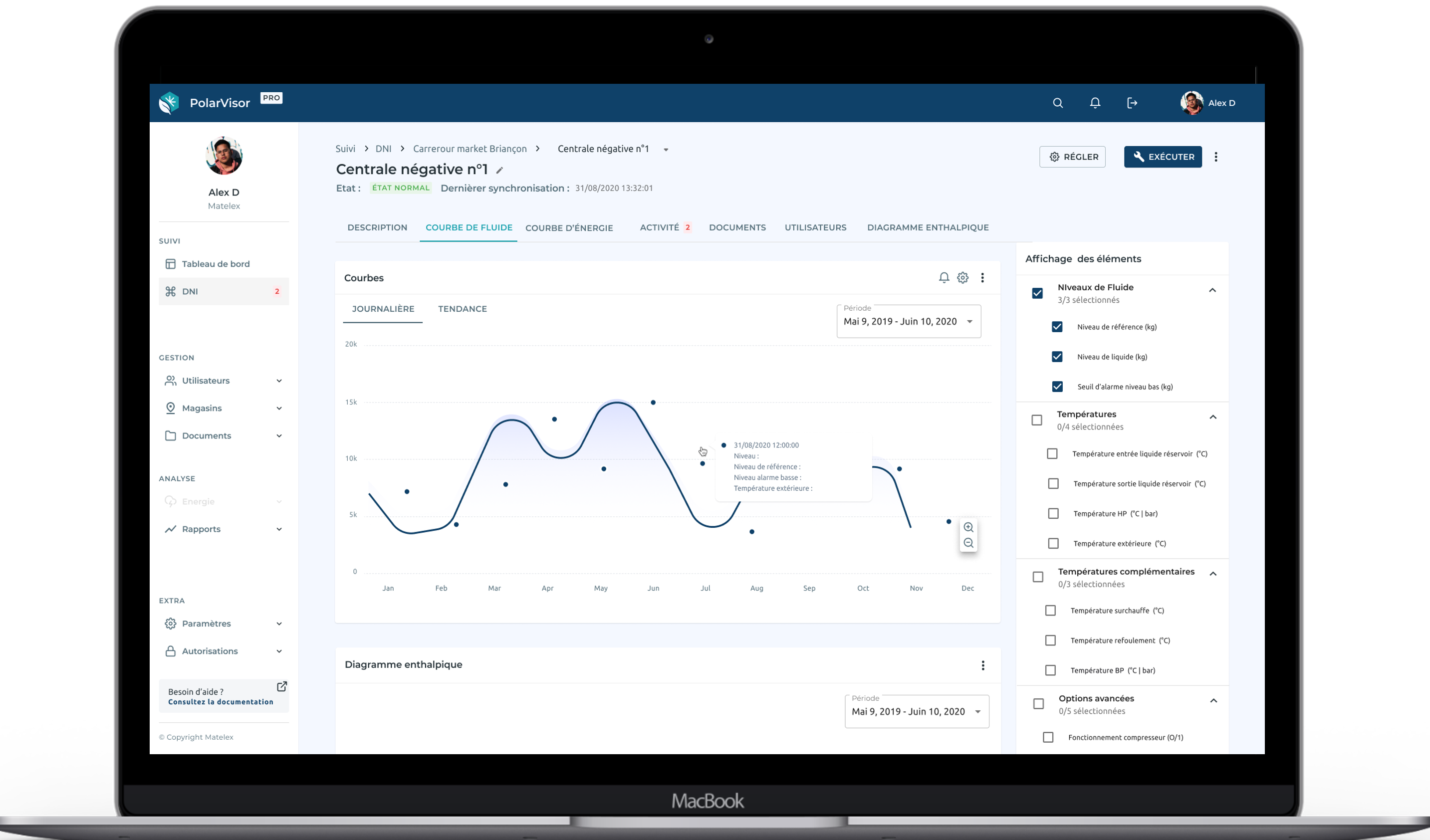

PolarVisor, a complete tool with multiple possibilities

PolarVisor takes the form of a web application associated with Matelex solutions. In simple terms, measurements taken on installations equipped with a DNI (intelligent level detector) and an Energy Module are transferred to PolarVisor, where they are analysed and displayed in the form of clear indicators.

| Good to know: the new generation of equipment known as PolarBox will soon be on the market. For more information, click here, it’s over here! |

view all its equipment from a general dashboard with a list of installations on alert; receive an alert if an energy drift, technical problem, compressor failure or refrigerant leak is detected; identify priority interventions; access operating data and refrigeration production efficiency; manage equipment remotely.

Much more than just an alert system, PolarVisor is also, and above all, an invaluable tool for optimising the settings of your installations. Thanks to all the data stored, you can generate customised reports and work towards improving your energy performance while reducing your operating costs.

In short, the IoT is becoming increasingly important for refrigeration professionals, because of its obvious logistical and economic advantages. Easy and quick to set up, these IT systems help to modernise your business efficiently and cost-effectively.

To find out more about our PolarVisor tool, click here!