Regulations • 14.10.2024

Direct and indirect greenhouse gas emissions: differentiating them to reduce them more effectively

In mid-September, the European Commission announced its intention to reduce greenhouse gas emissions by 55% by 2020, compared with the 40% initially planned. This ambitious target will be the subject of an amendment to the climate law, which will then have to be approved by the European Parliament and the Member States. To better understand the levers for action, we first need to differentiate between direct and indirect emissions, which are classified into 3 categories known as “scopes”.

Direct emissions – scope 1

ADEME (Agence de l’environnement et de la maîtrise de l’énergie) defines direct emissions as coming from fixed or mobile installations located within the organisational perimeter, i.e. emissions from sources owned or controlled by the organisation, such as : combustion from fixed and mobile sources, non-combustion industrial processes, emissions from ruminants, biogas from landfill sites, refrigerant leaks, biomass, etc. In other words, emissions linked to the use of oil in the manufacturing process of a product or those produced by the exhaust gases of a company’s fleet of lorries.

Indirect emissions – scope 2

These are emissions associated with the production of electricity, heat or steam imported for the organisation’s activities. The manufacture of a product, for example, will require energy consumption by the factories. This energy, which is not produced by the plant, still emits greenhouse gases and is therefore classified in Scope 2.

Other indirect emissions – scope 3

These are emissions not included in Scope 2 but linked to the entire value chain. They are not directly linked to the manufacture of a product, but rather to its entire life cycle. The extraction of materials used to manufacture raw materials, the transport of goods upstream or downstream or the recycling of a product are all part of Scope 3.

Reducing overall emissions from refrigeration therefore involves reducing these two types of emissions. Direct emissions linked to refrigerant leaks, and indirect emissions linked to the plant’s energy consumption.

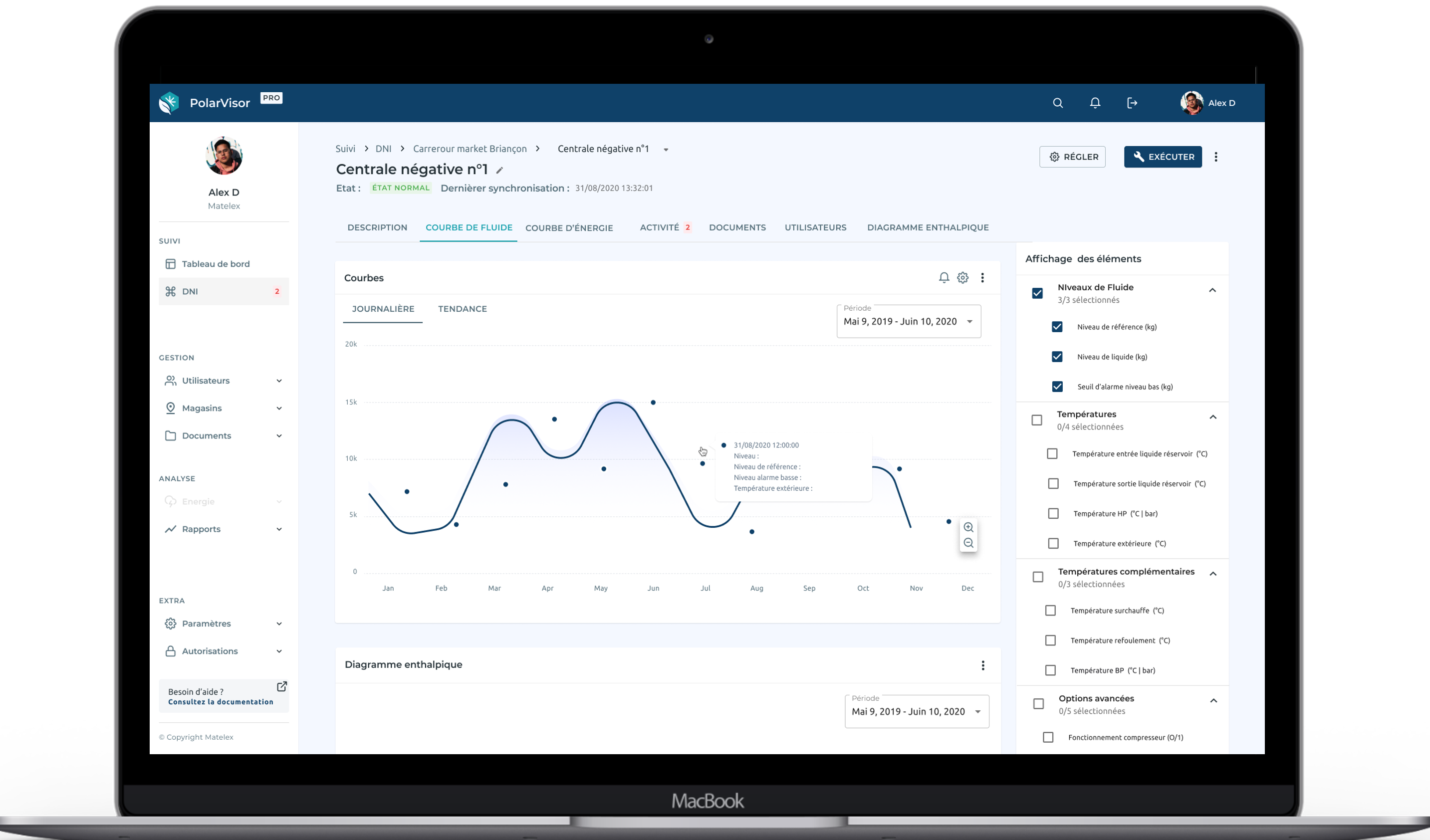

Thanks to real-time data, you can react quickly as soon as a leak occursConstant monitoring of the installations will help to achieve these objectives:

- Thanks to real-time data, you can react quickly as soon as a leak occurs

- The right refrigerant charge to avoid unnecessary over-consumption

- With the help of alerts and advice designed to optimise the energy consumption of your installations

Need advice or have questions?